Spring Pin IC Test Sockets

High-cycle spring-pin test sockets for reliable IC contact.

Engineered contact solutions tailored to your application.

Designed Around the Contact

Spring-pin test sockets succeed or fail at the contact interface. Rather than forcing a one-size-fits-all solution, Adapters-Plus designs each socket around the electrical, mechanical, and environmental requirements of the device under test.

We maintain a deep library of pogo-pin geometries, materials, and electrical variants, allowing us to tune contact compliance, force, bandwidth, and durability. This approach ensures consistent electrical performance while delivering a single, integrated socket solution tailored to your application.

Supported IC Package Types

Our spring-pin socket platforms support a wide range of surface-mount and array-based IC packages, including:

- BGA and LGA

- QFN and DFN

- QFP and TQFP

- SOIC, SOP, SSOP, and TSSOP

- Custom and non-standard packages

Pin counts range from low-I/O devices to high-density arrays. Fine-pitch layouts and mixed-signal designs are supported through appropriate pin selection and layout strategy.

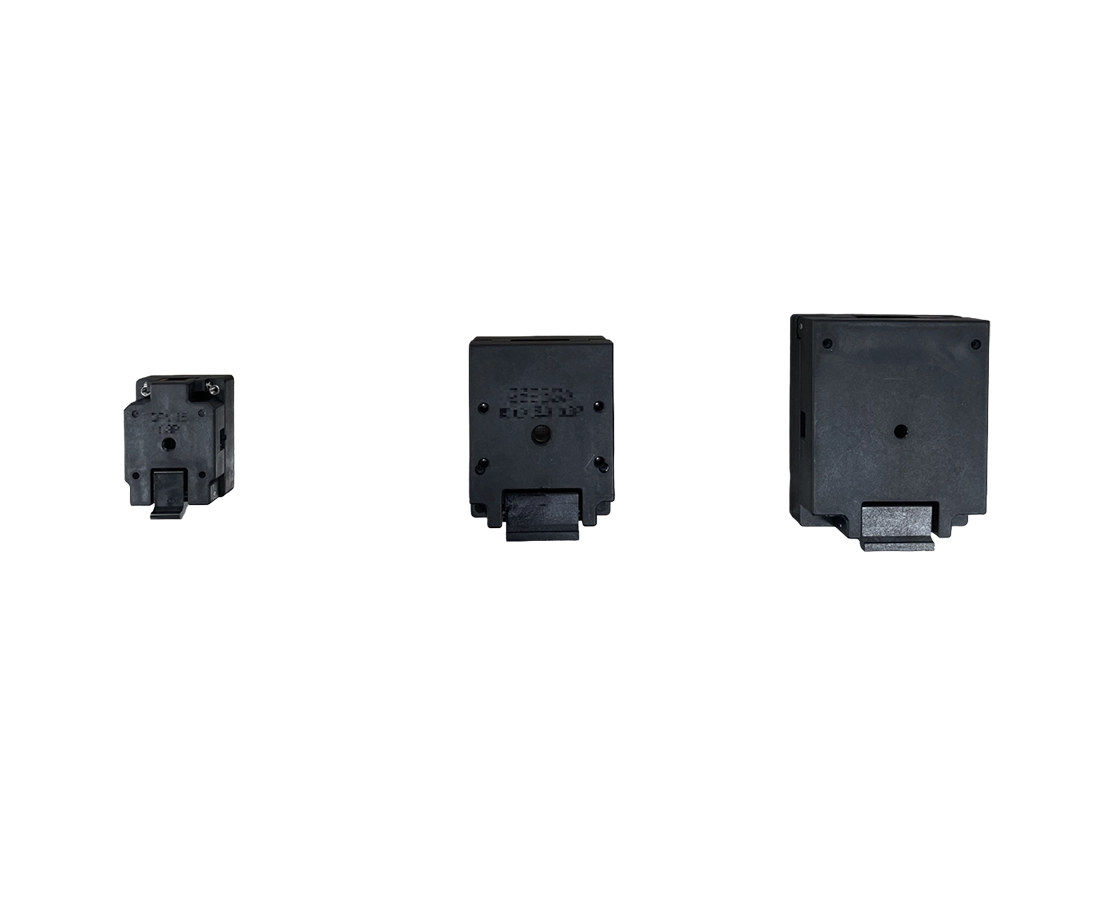

Socket Base Platforms

To balance customization with lead time and cost, most spring-pin sockets are built on one of three standardized base platforms. Each base serves as a mechanical foundation for custom pin fields, retention, and actuation features.

Base 100 — Compact Platform

- Body size: approximately 25 × 34 mm

- Supports devices up to ~14 × 14 mm

- Optimized for small QFN, QFP, and compact BGA packages

Base 200 — Mid-Size Universal Platform

- Body size: approximately 40 × 50 mm

- Supports devices up to ~24 × 24 mm

- Common choice for development fixtures and ATE

Base 300 — Large / High-I/O Platform

- Body size: approximately 50 × 61 mm

- Supports devices up to ~34 × 34 mm

- Designed for large BGAs and higher pin counts

While we do not sell pogo pins as stand-alone components, our socket designs draw from an extensive internal catalog of spring-pin technologies. This allows us to select the correct contact geometry and construction for each application without exposing customers to unnecessary complexity.

Depending on the device and test environment, sockets may incorporate:

- Single-ended or double-ended spring pins

- Ultra-fine pitch pins for dense layouts

- Kelvin (4-wire) pins for precision measurement

- High-frequency pins optimized for signal integrity

- Non-magnetic pins for sensitive applications

Pin parameters such as barrel diameter, travel, tip geometry, spring force, and plating are selected as part of the overall socket design—not left to chance.

Customization & Mechanical Options

Spring-pin sockets are typically configured to match your device handling, fixture constraints, and environmental requirements. Common options include:

- Clamshell, bottle-cap, and top-load retainer styles

- Manual cam locks and rotary locks

- Pneumatic / air-cylinder actuation

- Integrated heat sinks and thermal interface features

- Temperature sensors and embedded monitoring features

- Custom mounting patterns and PCB/fixture interfaces

If you have a non-standard package or clearance constraints around the device, we can design the retainer and actuation around your fixture envelope.

Typical Performance Specifications

Performance characteristics depend on the selected spring-pin type, tip geometry, pitch, and operating environment.

The values below represent typical ranges achieved in Adapters-Plus spring-pin test socket designs using standard and high-performance pogo-pin configurations.

| Contact Materials | Gold-plated copper alloy or beryllium copper (pin dependent) |

| Socket / Housing Materials | High-temperature thermoplastics, polyimide, FR-4 (configuration dependent) |

| Current Rating | Up to 1.0 A continuous per contact (higher available with specific pin selections) |

| Contact Resistance | ≤ 10 mΩ typical (pin and tip geometry dependent) |

| Bandwidth | DC to ~8–9 GHz (high-frequency pin configurations) |

| Contact Travel | 0.3 mm to 0.7 mm typical working range (pin dependent) |

| Contact Force | 20–30 gf typical per pin (application dependent) |

| Operating Temperature | -40 °C to +125 °C typical (extended ranges available) |

Final electrical and mechanical specifications are determined during socket configuration based on device requirements,

signal integrity needs, and environmental conditions.

Applications

Spring-pin sockets are commonly used across multiple test environments:

- Engineering bring-up and prototyping: rapid device swaps without soldering

- ATE and bench test: repeatable alignment and stable electrical contact

- Inspection and failure analysis: controlled engagement for diagnostics

- Burn-in / HAST: socket configurations tailored for thermal and humidity stress testing

- Characterization: consistent engagement for electrical performance measurement

Spring-Pin vs. BGA Locking Sockets

If your device is a BGA/LGA and you are deciding between socket types, these quick guidelines can help:

- Choose Spring-Pin when you need high insertion cycles, compliance for coplanarity variation, or configurable actuation.

- Choose BGA Locking Sockets (BL/LL Series) when you need footprint-compatibility, a compact locking socket format, or a socket that drops into an existing layout.

Why Adapters-Plus?

- Engineering-led support to align socket design with your device and fixture needs

- Standard base platforms to reduce lead time and control cost

- Custom options for actuation, thermal management, and sensors

- Built for repeatable testing with stable force and alignment over high insertion cycles

Request a Custom Spring-Pin Test Socket

Send your IC package drawing and test requirements. We’ll recommend the best base platform and configuration for your application.

Frequently Asked Questions

What is a spring-pin (pogo-pin) IC test socket?

A spring-pin IC test socket uses spring-loaded contacts to make temporary electrical connections to an IC without soldering.

The compliant contact helps accommodate package coplanarity variation while maintaining consistent electrical performance during repeated insertions.

When should I choose a spring-pin socket instead of a soldered or locking socket?

Spring-pin sockets are typically selected for applications requiring frequent device insertion and removal, tolerance compliance, or flexible test setups.

They are commonly used in engineering validation, ATE, failure analysis, and environmental testing.

For footprint-compatible, low-profile solutions, a locking BGA/LGA socket may be more appropriate.

Do you sell pogo pins as a standalone product?

No. Pogo pins are not sold as individual components.

They are selected and integrated as part of a complete spring-pin test socket design to ensure proper force, alignment, signal integrity, and long-term reliability.

How are spring-pin tip styles selected for an application?

Tip geometry is chosen based on the device termination type, pitch, surface finish, and test requirements.

For example, crown tips are often used for BGA solder balls, while flat or Kelvin tips may be specified for precision measurement or specialized applications.

Tip selection is part of the overall socket engineering process.

What electrical performance can be expected from spring-pin contacts?

Electrical performance depends on pin type and configuration, but spring-pin contacts are commonly designed to support low contact resistance, controlled impedance paths, and multi-GHz signal bandwidth.

For background reference on contact resistance and probe behavior, see:

https://en.wikipedia.org/wiki/Pogo_pin

Are spring-pin sockets suitable for high-frequency or high-speed signals?

Yes, when designed correctly.

High-frequency spring-pin configurations are commonly used in RF and high-speed digital testing, with attention paid to pin geometry, grounding strategy, and signal path length.

General signal integrity considerations are outlined by IPC standards such as:

https://www.ipc.org/standards

What information is needed to quote a custom spring-pin test socket?

To evaluate a socket design, we typically request an IC package drawing, pin count and pitch, test environment details, and any mechanical or thermal constraints.

Providing complete information helps ensure the correct base platform, contact type, and retention method are selected.