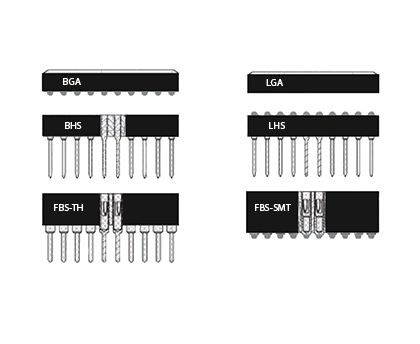

BGA / LGA Headers & Mating Sockets

Board-level interconnects for BGA and LGA devices.

Designed to mate with matching receptacle sockets.

Quick Selection Guide

Start with how your device attaches, then select the header style and the appropriate

FBS receptacle based on footprint, assembly requirements, and pitch.

BHS SERIES — DEVICE SOLDERS TO HEADER

- Use when: the BGA device solders directly to the top-side interface

- Best for: robust header-based interconnects with defined stack height

- Mates with: FBS receptacle sockets (SMT or through-hole)

LHS SERIES — INTERPOSER-STYLE INTERFACE

- Use when: solder balls on the adapter mate to an LGA interface or SMT BGA footprint

- Best for: interposers, footprint translation, and multi-chip modules

- Mates with: FBS receptacle sockets matched to the target PCB

FBS SERIES — MATING RECEPTACLE OPTIONS

- FBS SMT (solder-ball): low-profile, reflow-compatible attachment for compact stack-ups

- FBS Through-Hole: enhanced mechanical retention for serviceable or rugged assemblies

FBS Series Female Receptacle Sockets

The FBS receptacle provides the mating interface for both BHS and LHS headers.

Select the mounting style that aligns with your PCB design and assembly process.

FBS SERIES SMT (SOLDER-BALL)

- Low-profile SMT attachment for compact stack-ups

- Reflow-compatible assembly for production builds

- Common in interposers, adapters, and validation boards

FBS SERIES THROUGH-HOLE

- Through-hole termination for secure PCB mounting

- Enhanced mechanical retention and durability

- Common in prototype fixtures and rugged lab hardware

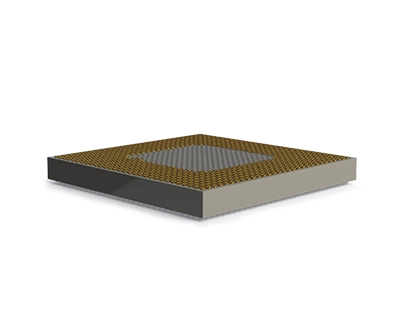

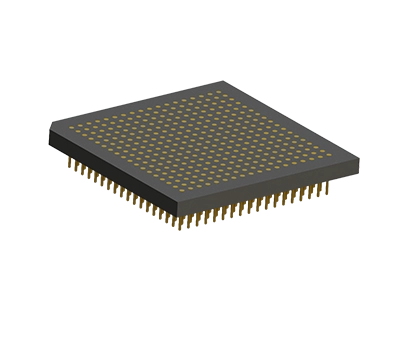

LHS SERIES (SOLDER-BALL INTERFACE)

- Solder-ball interface for LGA and SMT BGA footprints

- Ideal for interposers and footprint translation

- Common in multi-chip modules and compact adapters

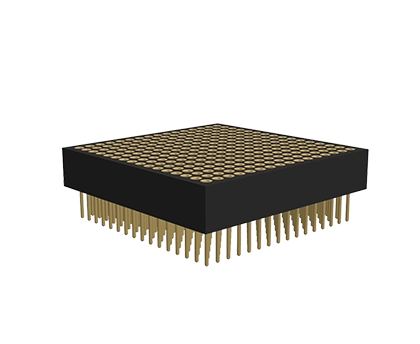

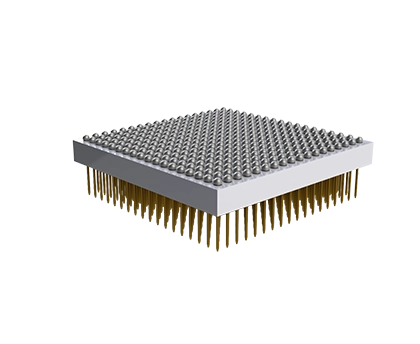

BHS SERIES (DEVICE-SOLDER INTERFACE)

- Top-side pads for direct BGA device soldering

- Robust header interface with controlled stack height

- Common in development, validation, and repeatable mating

Common Pairings

Most designs combine a BHS or LHS header with a matching FBS receptacle.

The correct pairing depends on how the device attaches and how the PCB is built.

| BHS + FBS | BGA device solders to the header and mates into a board-mounted receptacle. |

| LHS + FBS | Interposer-style solution for LGA interfaces or SMT BGA footprints using solder balls on the adapter. |

| FBS SMT vs Through-Hole | Choose SMT for compact reflow builds or through-hole for mechanical robustness and serviceable assemblies. |

Typical Applications

- Interposer adapters: translate device footprints or create a testable interconnect layer

- Multi-chip modules: controlled stack height for dense assemblies

- Development & validation: repeatable mating during lab bring-up and characterization

- Footprint alignment: solutions designed around existing PCB land patterns

Information Needed to Specify the Right Solution

Provide any available device and PCB details, and we’ll recommend the correct

header and receptacle combination.

- Pitch: 1.27 mm, 1.00 mm, or 0.80 mm

- Array size: ball / pad count and pattern

- Target footprint: BGA land pattern or LGA interface

- Mounting style: SMT or through-hole

- Constraints: stack height, keep-out zones, mechanical clearance

- Assembly method: reflow, selective solder, or hand solder

Related Test & Interconnect Solutions

These categories are often selected alongside BGA/LGA headers and receptacle sockets

for validation, characterization, and production support.

- BL / LL Series BGA & LGA Test Sockets

– Spring-contact test sockets for development, validation, and burn-in. - Spring Pin IC Test Sockets

– Pogo-pin based sockets for repeatable electrical contact during development and production test.