PCB Headers & Interconnects

Overview

Headers and mating sockets form the mechanical and electrical bridge between the device under

test and the system hosting it. Properly selected interconnect hardware improves contact

reliability, protects the PCB, and enables modular adapter and fixture designs.

Repeatable Engagement

Consistent mating improves signal integrity and reduces wear on the target PCB.

Serviceable Interfaces

Interconnects can be replaced or reconfigured without redesigning the adapter.

Modular Stack Height

Clearance can be built in for dense layouts, tall components, or retention hardware.

Interconnect types

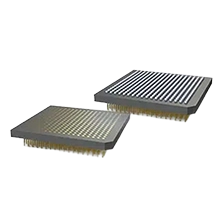

BGA / LGA Headers & Mating Female Receptacle Sockets

stacks, clearance management, and fixture-friendly interfaces.

DIP Headers & Mating Sockets

and production replacement applications.

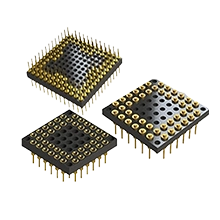

PGA Headers & Mating Sockets

Pin-grid interconnects for high pin-count devices where engagement consistency

and mechanical stability are critical.

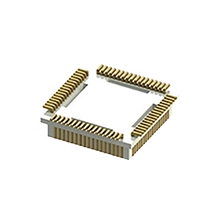

PLCC Emulator Plugs

emulation and programming applications.

Specifying the Correct Interconnect

Selecting the appropriate header and mating socket starts with understanding the device

interface, PCB constraints, and intended use. In many cases, existing footprints can be reused,

or a new footprint can be defined to match specific mechanical or electrical requirements.

Device Interface

- Package type and pin or ball count

- Pitch and orientation

- Keying or alignment features

PCB Constraints

- Existing footprint or land pattern

- Component keep-out zones

- Required stack height

Use Case

- Prototyping, production test, or burn-in

- Insertion cycle expectations

- Handling or environmental constraints

Custom & Technical Guidance

When standard configurations are not a perfect fit, our engineering team designs and builds

custom interconnect solutions to match your footprint, stack height, and mechanical

requirements. Built-to-order solutions typically ship in 2–4 weeks, depending on complexity.