Production Replacement Adapters

Overview

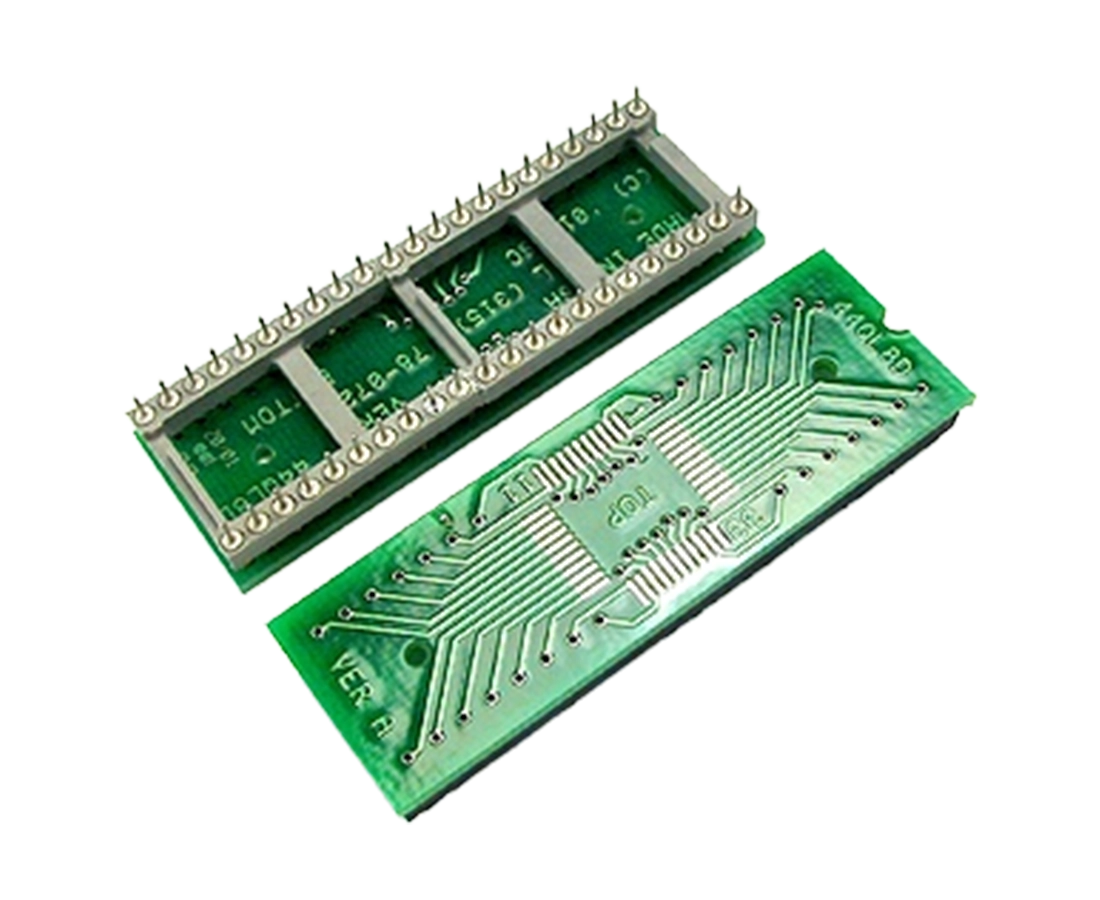

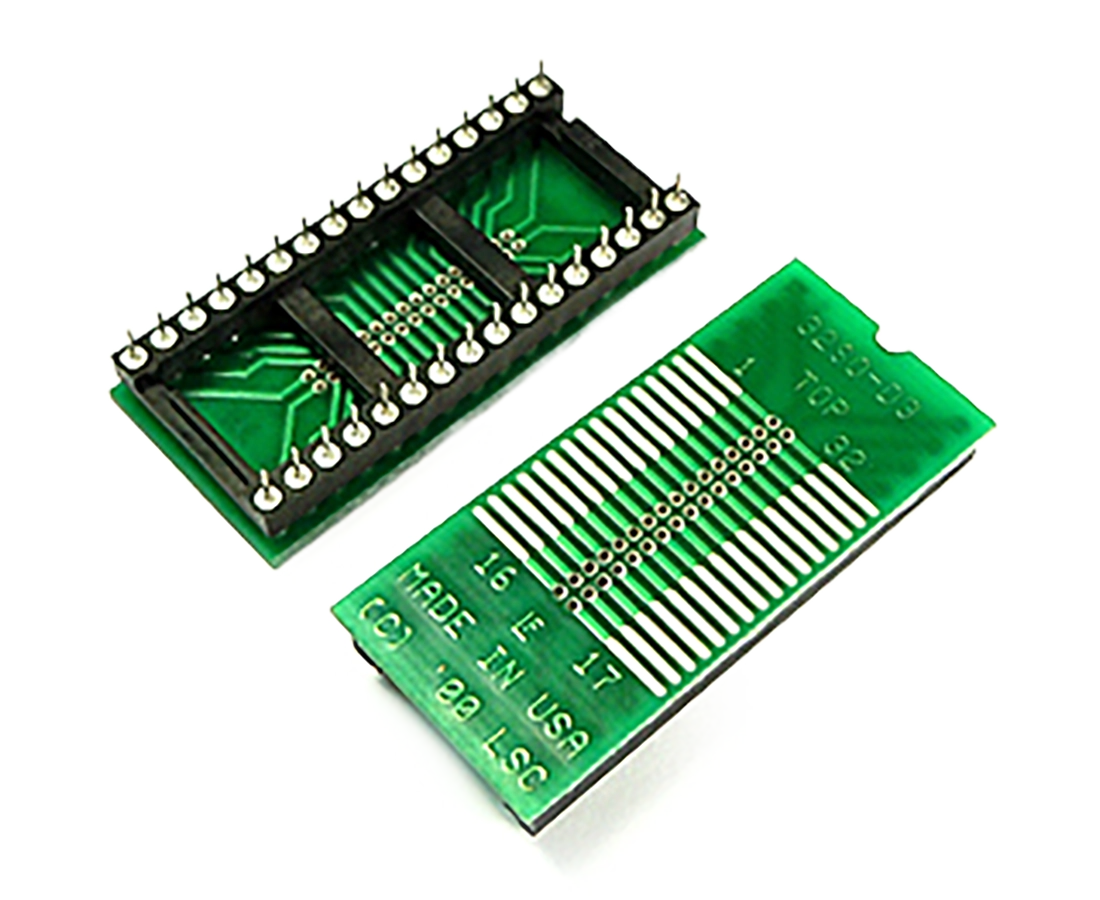

Production replacement adapters convert surface-mount device footprints to DIP form factors,

allowing modern ICs to be used in sockets, breadboards, and legacy through-hole systems.

Each adapter is designed with a precise SMT land pattern on the top side and routes signals

to a standard DIP pin format on the bottom side.

This approach prioritizes mechanical simplicity and electrical clarity, making these adapters

suitable for production replacement, engineering evaluation, and lab environments.

Surface-Mount to DIP Conversion

Each production replacement adapter incorporates an accurate surface-mount land pattern that

matches the target IC package footprint. Signals are routed directly to a DIP interface to

ensure predictable electrical behavior and compatibility with standard through-hole systems.

- Accurate SMT footprints for reliable solder attachment

- Standard DIP pin spacing for easy handling

- Straightforward pin mapping for predictable electrical behavior

- Compact layouts suitable for repeated insertion and removal

Applications

-

Production adapter replacement:

Replace damaged, worn, or unavailable production adapters without redesigning hardware. -

Engineering and lab use:

Bench testing, troubleshooting, and device evaluation using standard DIP sockets. -

Low-cost prototyping:

Validate devices before committing to custom PCBs or fixtures. -

Short-run or legacy testing:

Useful when volumes or timelines do not justify custom tooling.

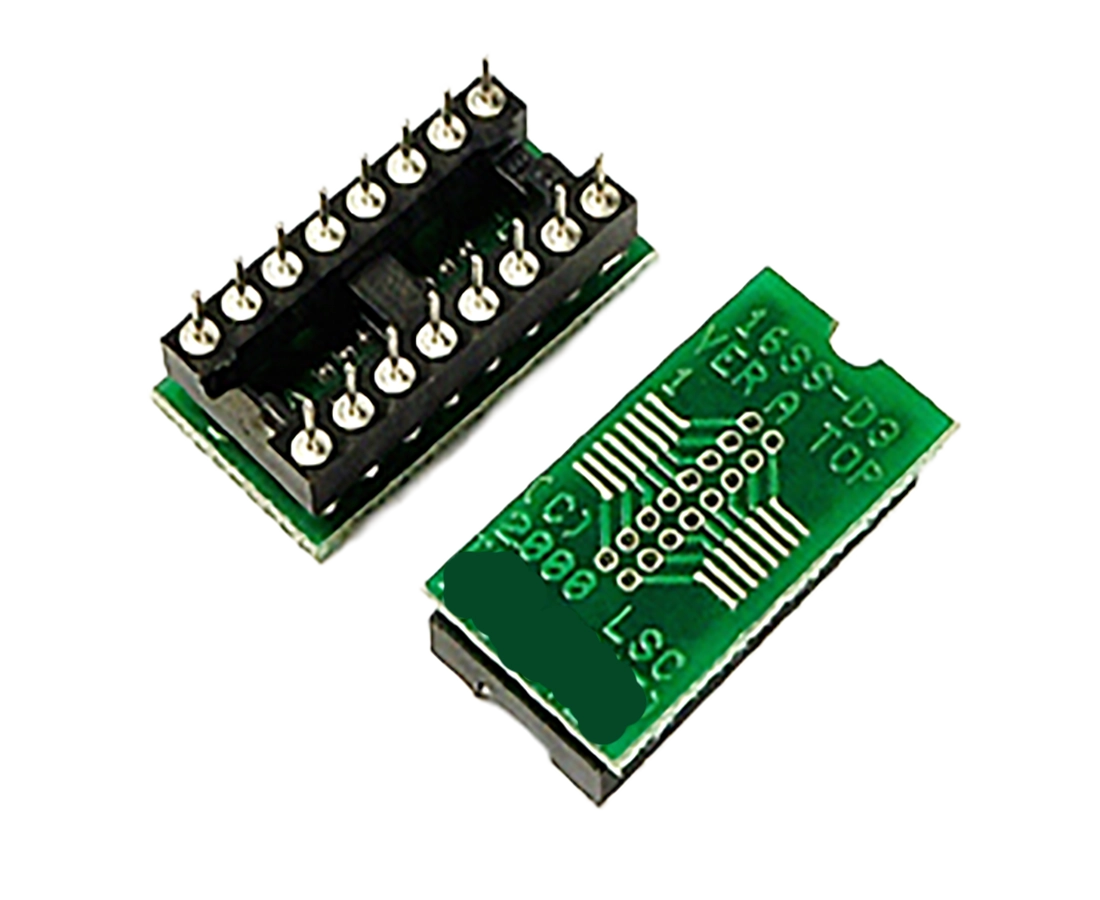

Top: SOIC (SMT) device interface

Bottom: DIP through-hole

SMT SSOP & TSSOP to DIP Adapters

Top: SSOP / TSSOP (SMT) device interface

Bottom: DIP through-hole

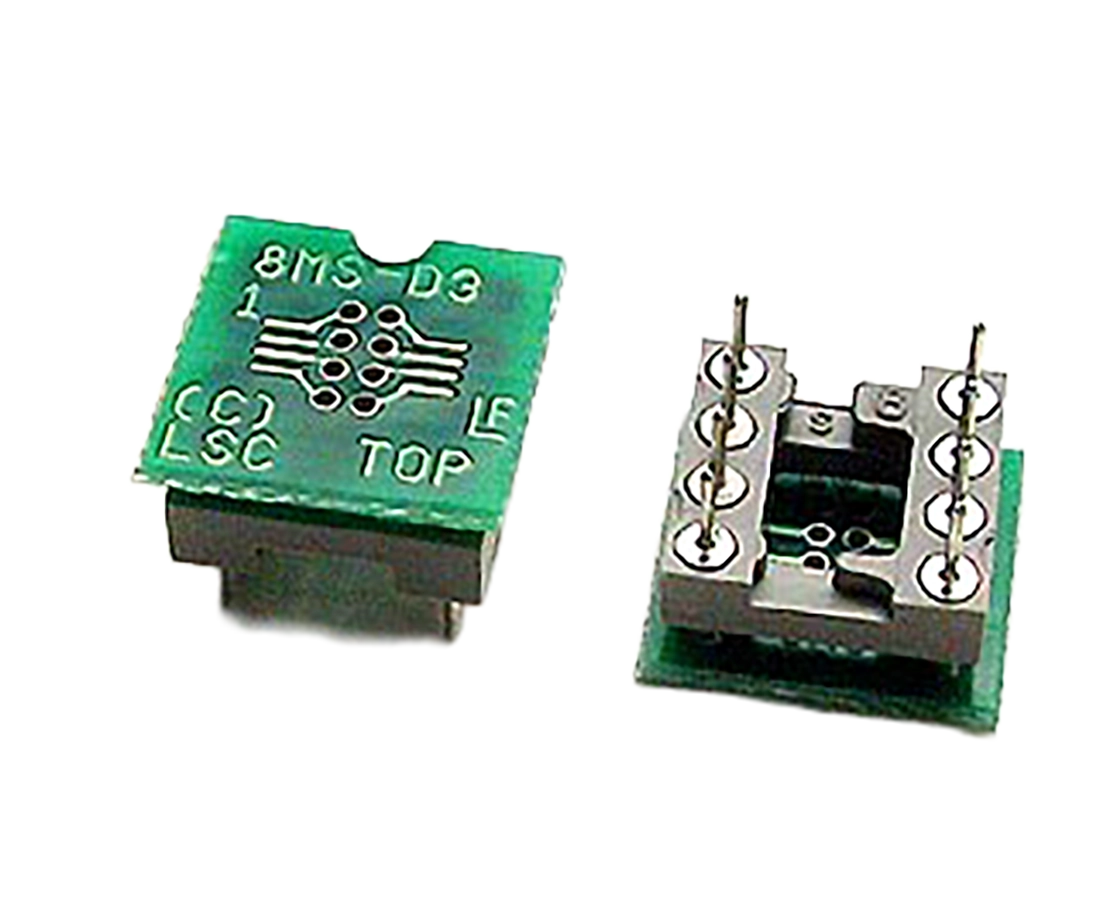

SMT MSOP & SOT to DIP Adapters

Top: MSOP / SOT (SMT) device interface

Bottom: DIP through-hole

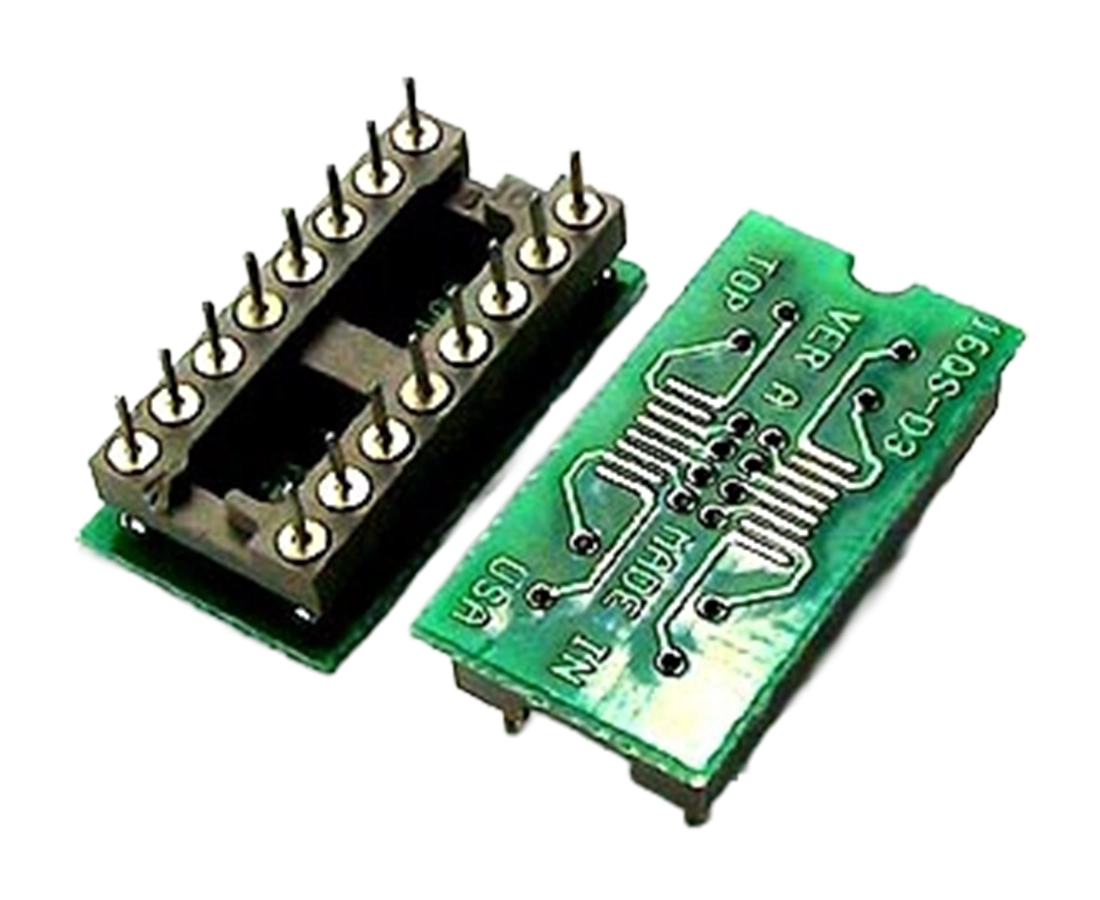

SMT QSOP & TSOP to DIP Adapters

Top: QSOP / TSOP (SMT) device interface

Bottom: DIP through-hole

SMT Quad, PLCC, QFN & QFP to DIP Adapters

Top: Quad / PLCC / QFN / QFP (SMT) device

Bottom: DIP through-hole

Turn-Key Assembly Options

For customers who need a ready-to-install solution, Adapters-Plus can provide turn-key assembly

on production replacement adapters. This may include sourcing the specified device, soldering

it to the adapter, and delivering a fully assembled unit.

- Device procurement from customer-specified or approved sources

- Professional soldering for fine-pitch and leadless packages

- Support for universal and 1-to-1 adapter configurations

- Functional verification as defined by the application

Turn-key assembly is most useful when time-to-deployment is critical or when in-house assembly

resources are limited.

Custom & Technical Guidance

If your fixture, device package, or pinout requires a non-standard interface, our engineering

team can design a production replacement adapter that matches your manufacturing constraints

and reliability requirements.