IC Production Test Adapters

Fixture-based adapters engineered for repeatable, high-cycle manufacturing and validation testing.

What Is an IC Production Test Adapter?

IC production test adapters are interface assemblies used during manufacturing, validation,

and production screening of integrated circuits. They provide the physical and electrical

interface between a packaged device and the test system performing functional, parametric,

or reliability testing.

In production environments, these adapters allow devices to be tested within the constraints

of an established test setup. This may involve adapting a device to an existing production

board footprint, load board, emulator pod, or fixture interface without requiring changes

to the underlying test hardware.

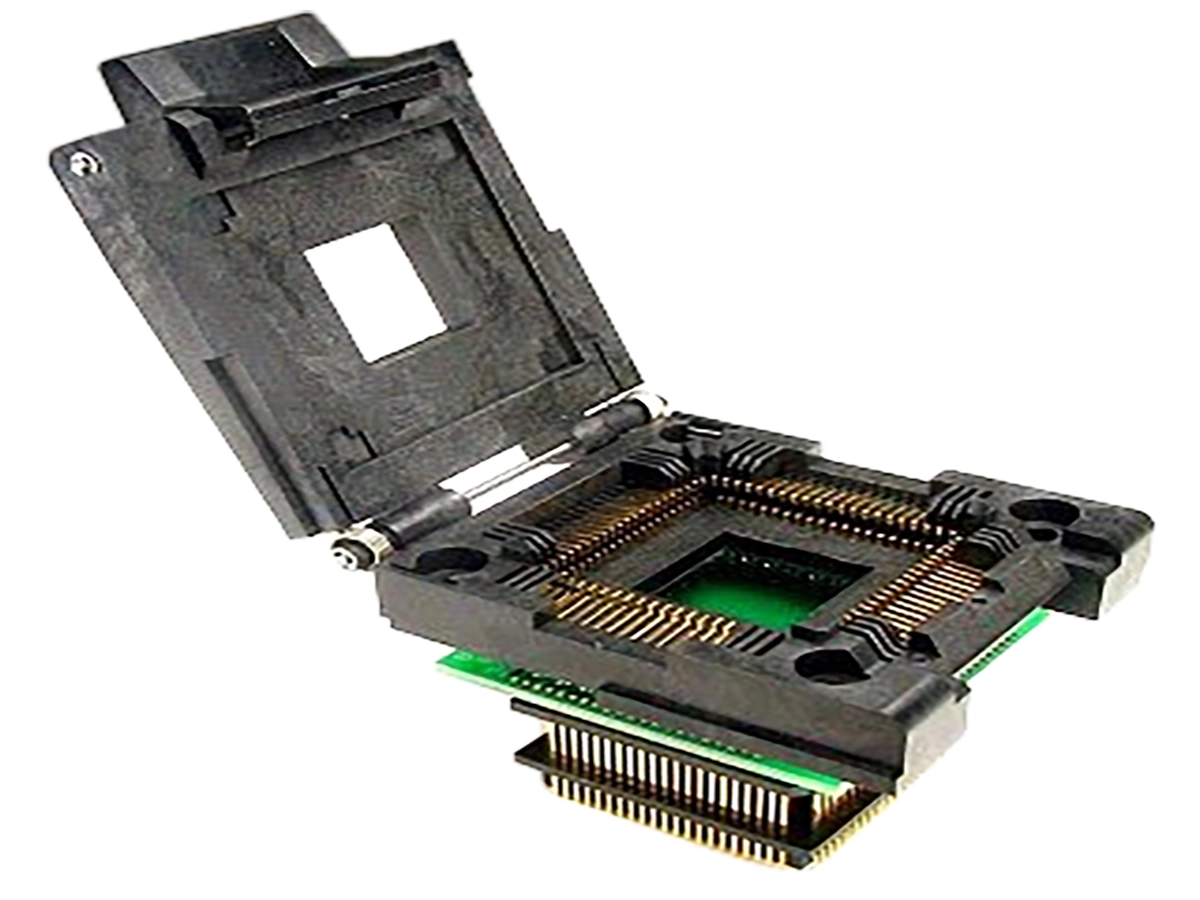

Depending on the application, a production test adapter may present a socketed top interface

to accept the device under test, or it may provide a package-to-package translation that mates

directly with an existing interface such as a DIP plug, PLCC socket, or other legacy or

standardized footprint. These adapters help maintain continuity between development,

validation, and production test flows when device packaging differs from the production

test interface.

The primary role of a production test adapter is not development convenience, but reliable

electrical and mechanical interfacing that enables accurate testing within real-world

manufacturing constraints.

Examples of Adapters Used in Production Testing

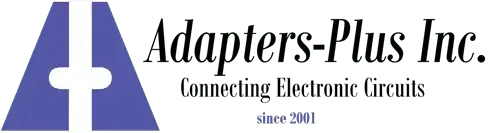

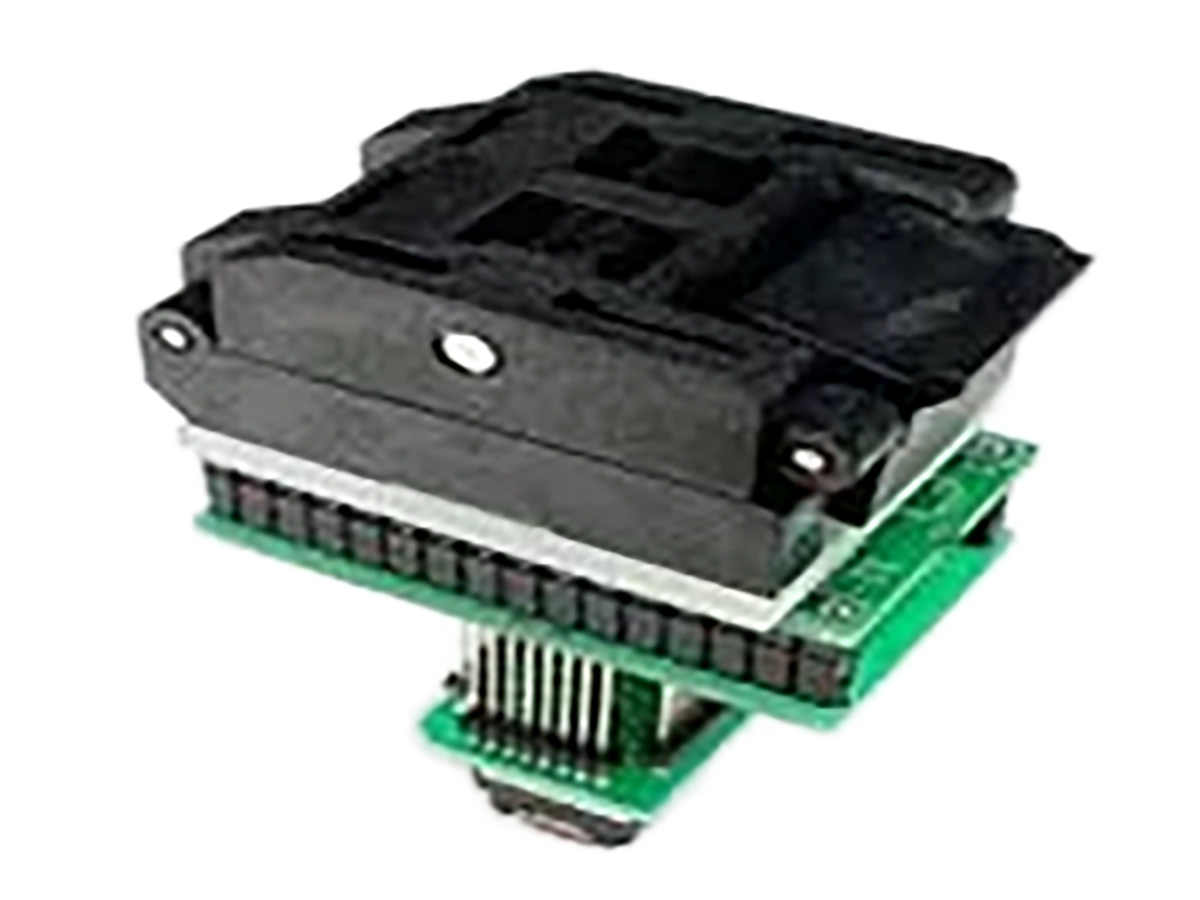

Top: DIP interface

Bottom: PLCC production plug

Used to test PLCC devices in production fixtures designed around a DIP interface.

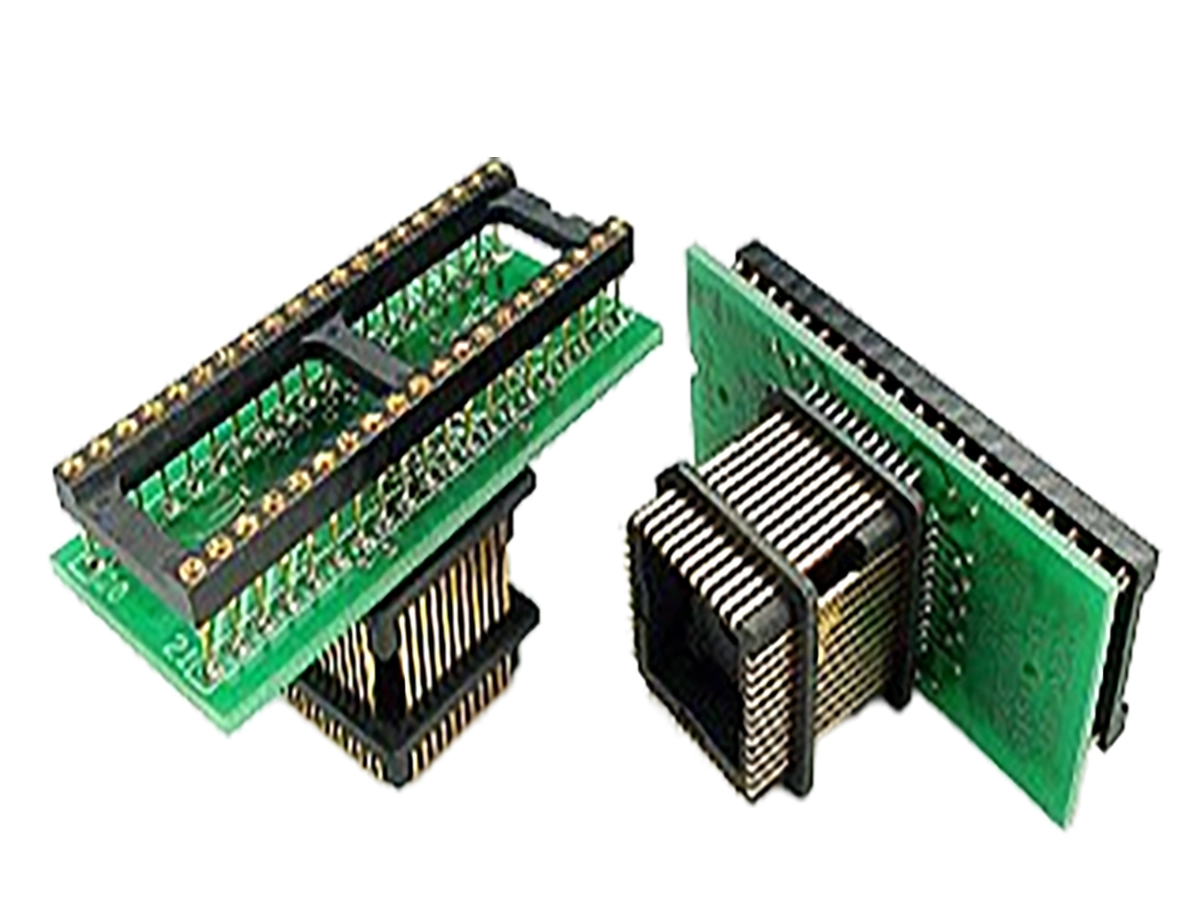

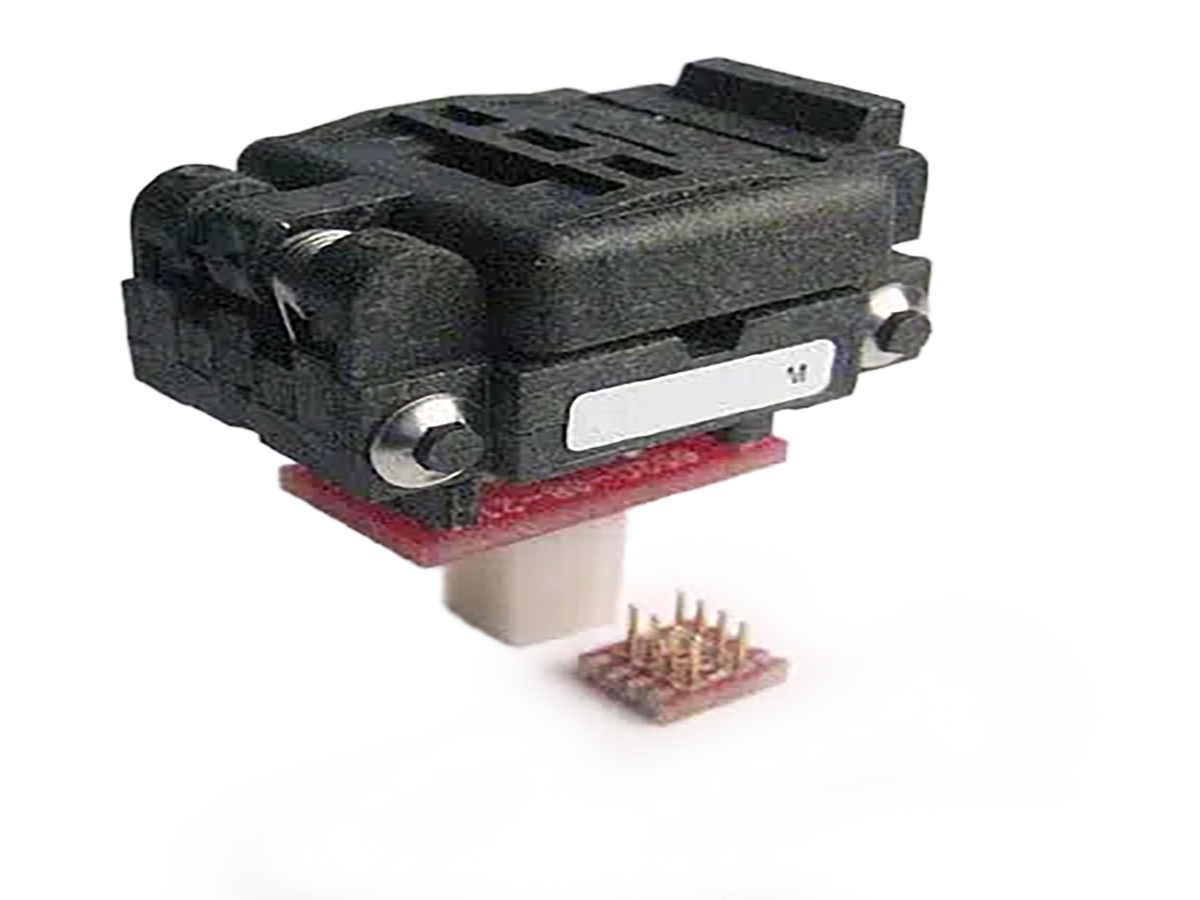

Top: DIP interface

Bottom: SOIC footprint

Used to test SOIC devices in production fixtures designed around a DIP interface.

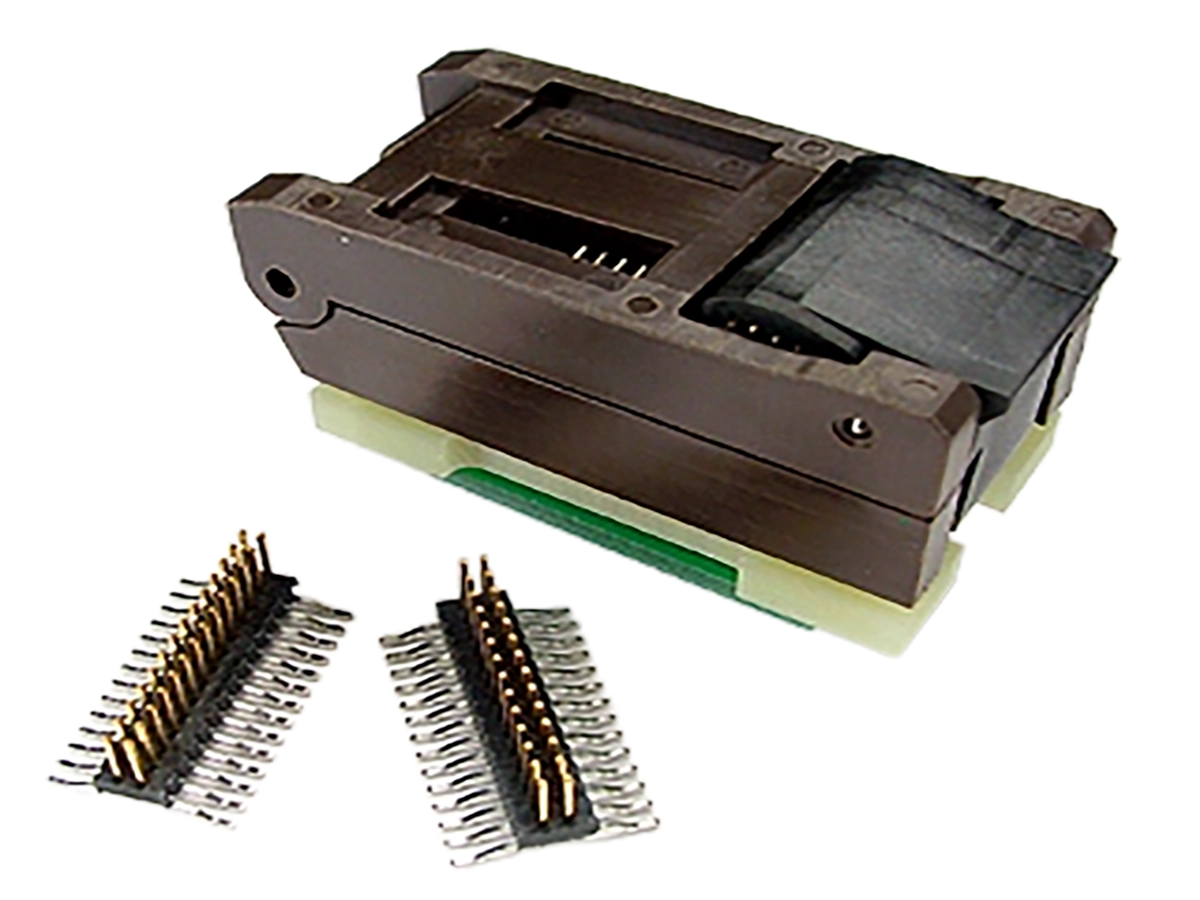

Top: PLCC interface

Bottom: PLCC production plug

Used to test PLCC devices in production fixtures requiring same-package interfacing.

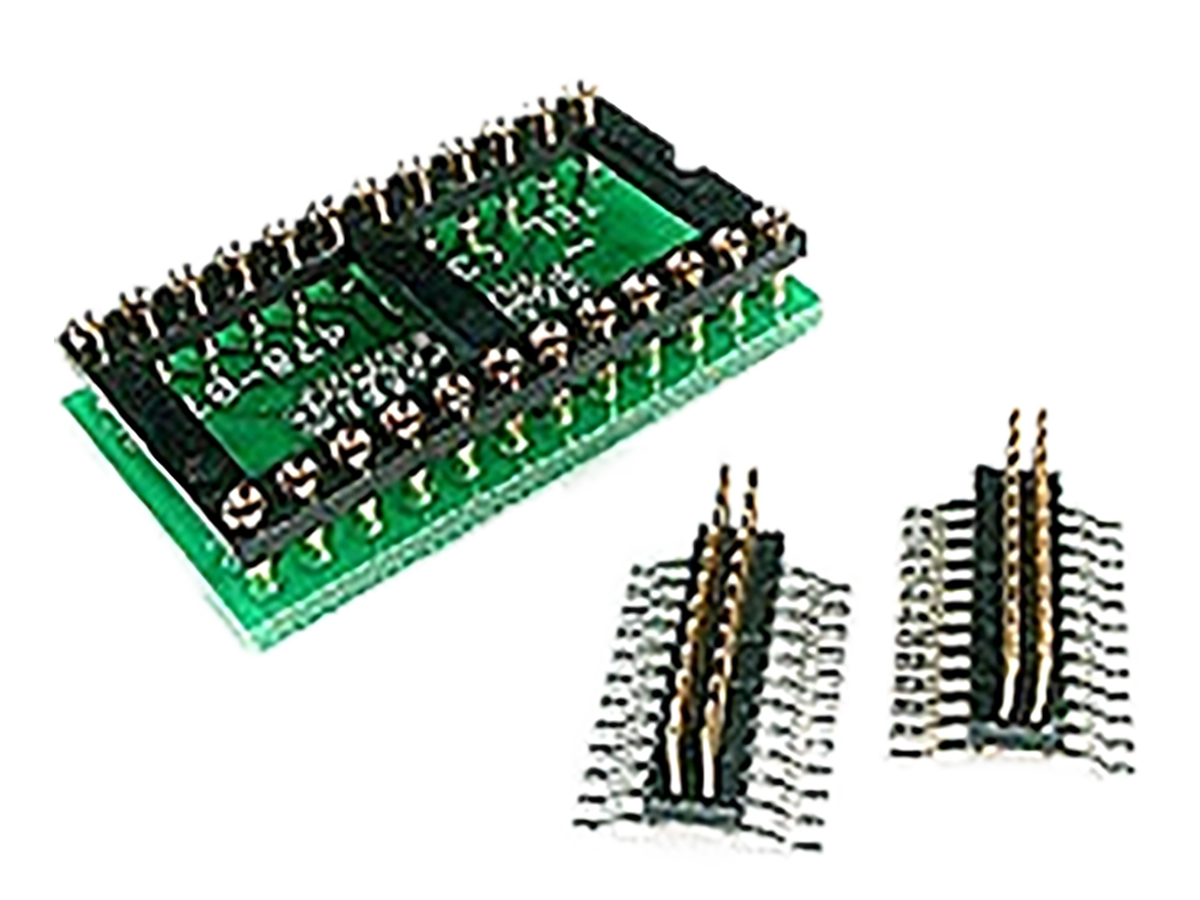

Top: QFP interface

Bottom: QFP footprint

Used to test QFP devices in production fixtures requiring same-package interfacing.

Top: QFN interface

Bottom: QFN footprint

Used to test QFN devices in production fixtures designed for leadless packages.

Top: SOIC interface

Bottom: SOIC footprint

Used to test SOIC devices in production fixtures requiring same-package interfacing.

Design Priorities for Production Testing

Production test adapters are engineered with manufacturing constraints in mind.

Typical design priorities focus on mechanical robustness, alignment accuracy,

and repeatable electrical performance within production environments.

- Mechanical stability for fixture-based use

- Precise alignment features to ensure consistent device seating

- Robust contact systems suitable for high insertion counts

- Controlled tolerances to minimize measurement variation

- Compatibility with manual, semi-automated, and automated test fixtures

These considerations help ensure reliable electrical performance throughout

production workflows while maintaining compatibility with existing test infrastructure.

Custom Production Test Adapters

When standard interfaces do not meet fixture, device, or pinout requirements,

custom production test adapters can be designed to match specific manufacturing

constraints and test environments.

Custom solutions may support:

- Unique pin mappings or signal reassignments

- Package size or form-factor variations

- Fixture-specific mechanical envelopes and clearances

- Specialized contact, retention, or alignment requirements